JL-100VG - HIGH PRECISION CNC VERTICAL ROTARY GRINDER

Model: JL-100VG

Category: Semiconductor Smart Auto Solution

Exhibitor: JOEN LIH MACHINERY CO., LTD.

Booth No: N308

Characteristic

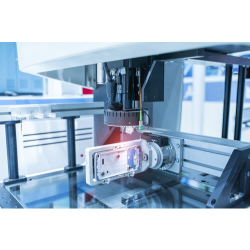

The Joen Lih JL-100VG CNC Vertical Grinder is designed specifically for internal and external diameter grinding on cylindrical parts. With its double column structure and the use of a rotary table with loading capacity up to 1200kg, the machine fully presents exceptional stability. As a result, high cylindricity accuracy can be achieved.

1. DOUBLE COLUMN STRUCTURE OUTSTANDING RIGIDITY AND GRINDING STABILITY

- All machine structural parts are manufactured from high quality cast iron, stress relieved to ensure deformation-free structure as well as grinding accuracy for many years.

- The X-axis is mounted with linear guideways, and steel guideways on Z-axis, to balance the wheel head stability and rapid traverse rate.

- The machining area is designed with an opening, allowing the operator to use lifting devices electronic crane for convenient loading/unloading of workpieces.

2. MACHINE FEATURES

- Internal grinding size Ø50~Ø950 mm

- Max. external grinding size Ø1250 mm

- The double column machine structure provides superior grinding stability and quality

- The wheel head tilts 22.5°

- Equipped with a built-in type high speed wheel spindle

- Automatic tool changer for increasing efficiency

- CNC controller provides user-friendly operation

- Fully enclosed splash guard with opening on top of machine makes workpiece loading /unloading more convenient。

3. HYDROSTATIC ROTARY TABLE

- Rotary table diameter is 1050 mm.

- Maximum load of table is 1200 kg.

- Choice of magnetic chuck, gripper and automatic jig, and fixture for clamping workpiece.

- Independent hydraulic system allows for precise control of hydraulic temperature. Hydrostatic rotary table won‘t contact bearing, thus no issues of noise, friction and thermal deformation on workpiece.

4. AUTOMATIC TOOL CHANGER

- The tool loading capacity of the magazine is 6 grinding wheels.

- Fast tool change with smooth motions.

- Tool shank type is HSKA100

5. A BUILT-IN TYPE WHEEL SPINDLE

- The wheel spindle features high running speed, high precision, low vibration, low noise, light weight, and low thermal displacement.

- Linear speed of grinding wheel <33m/s.

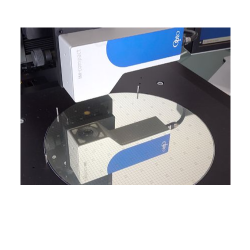

6. ONLINE MEASURING DEVICE (OPTIONAL)

The online measuring device is used for measuring the height, inner and outer diameters of a workpiece. One probe touches the ring gauge, and the other probe touches the workpiece to compare the machining accuracy.

7. RING GAUGE

- The ring gauge is mounted on the base.

- The ring gauge is used for checking, calibrating comparing the machining accuracy of a workpiece.

8. WHEEL DRESSER

- The wheel dresser is mounted on the base. Two-axes inclinable wheel dresser avoids machining interference and saves space.

- Applicable for dressing the profile of the grinding wheel.

Other Products

Products you may be interested in

Highest Rated Products