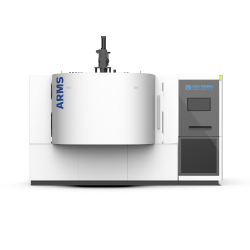

ARMS Coating Machine

Category: Electronic Production Manufacturing Equipment

Exhibitor: DAH YOUNG VACUUM EQUIPMENT CO., LTD.

Booth No: N328

Characteristic

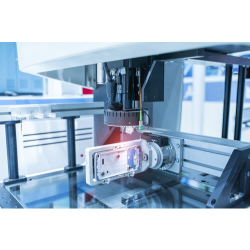

In addition to the field of evaporation optics, Dahyoung Vacuum has developed its own Activated Reactive Magnetron Sputtering equipment to introduce the characteristics of the sputtering process into the optical field. The Activated Reactive Magnetron Sputtering equipment can effectively improve the two main shortcomings of the reactive sputtering process caused by target poisoning, by separating the interaction between the sputtering and the reactive gas:

Low plating rate.

The target surface discharge destroys the film quality.

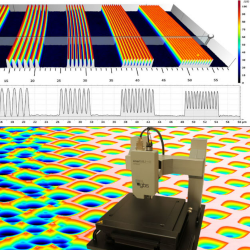

The Activated Reactive Magnetron Sputtering method has a target area and a plasma source area. This plasma source area can also be called a coupled plasma area. During the process, an inert gas is introduced into the target area, and a mixed reactive gas is introduced into the plasma area to reduce the influence of the reactive gas on the target during the sputtering process. The process has high stability and the sputtering process is still maintained. The advantages are high film quality with large area and high uniformity coating.

Because the sputtering process has high molecular kinetic energy and better step coverage, it overcomes the limitation of non-planar substrates to a certain extent, so that even substrates with curved surfaces can be used to prepare uniform optical films. This feature is very suitable for use in vehicle lens for the self-driving car industry.

Dahyoung Vacuum introduces this sputtering process into its optical coating equipment. On the one hand, it introduces the advantages of sputtering, and effectively improves the shortcomings of reactive sputtering, and further gives the equipment "high plating rate", "high film quality", and "high stability" Performance.

Other Products

Products you may be interested in

Highest Rated Products